The UAE’s building industry is booming, and the need for high-quality materials keeps growing. Anodized aluminum sheets and GI perforated sheet are two of the most popular materials. Both are quite durable, look good, and work well, so they are great for many building projects. These materials are stylish and strong enough to suit the needs of modern design and construction, whether they are used for exterior cladding, interior decorations, or utilitarian functions.

What is anodized aluminum sheet, and why is it important in building?

An anodized aluminum sheet is a metal product that has a protective oxide layer on its surface. This layer is formed by an electrochemical process called anodization. This method produces the material much more resistant to corrosion, more durable, and more appealing. Avoiding any damage to the sheet, the anodized layer also provides it with a certain shine that in many cases improves its color, texture, and overall appearance.

Anodized aluminum is easily available in UAE because the weather in that region is extreme and needs materials that are able to withstand high temperatures and corrosive salt water. No other treatment is as protective of architectural facades, window frames, and exterior cladding as anodized finish. This maintains the buildings in good and functioning condition over a long period.

GI Perforated Sheet: This Material Can be utilized in a lot of ways.

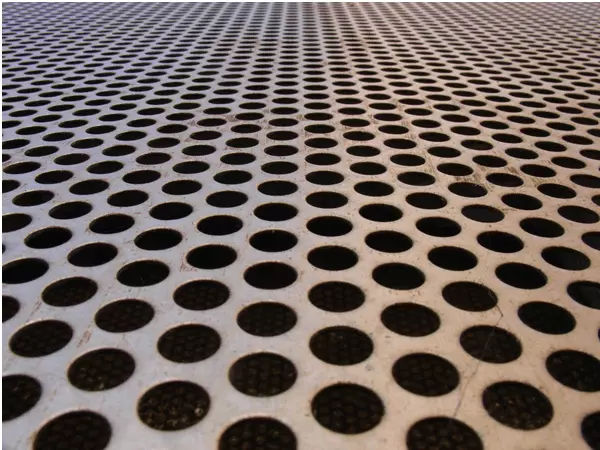

The GI Perforated Sheet is a flexible sheet made of galvanized iron (GI) that is used in various industries, one of which is building. The perforation process creates a sequence of holes or openings in a sheet that can make it appear better and perform better. These sheets are tough, durable and can withstand the weather, making it a good indoor and outdoor sheet in the diverse weather of the UAE.

You can use GI perforated sheets to alter the size, shape and pattern of the holes and they can be used in a lot of different types of projects. These sheets are also fundamental to construction work at present days, be it the manufacture of ventilation panels, ornamental screens, or ornamental features. They are powerful yet lightweight, which can be used in a variety of applications, including industrial buildings, business premises, and residential houses.

A Comparison of Anodized Aluminum Sheets with GI Perforated Sheets

In the UAE, both Anodized Aluminium Sheet and GI Perforated Sheets are good for construction projects in different ways. The main distinctions are in the materials they are made of, how they look, and how well they work for certain tasks.

People really like anodized aluminum sheets because they may look good in a lot of different ways. Anodizing not only protects aluminum, but it also lets you choose from a wide range of hues and finishes, such as matte, gloss, and shiny. Due to this, anodized aluminum is much used in architecture where appearance is of equal importance to strength.

Conversely, GI Perforated Sheets are ideal where airflow is required and strength is desired. Pores in the perforated sheets allow air and light to pass through and this makes them ideal to be used in commercial and residential buildings as facades, partitions and decorative elements.

Anodized aluminum is very attractive and shiny and in situations where functionality and performance count the most, GI perforated sheets are generally the best option.

Conclusion

GI perforated and anodized aluminum sheets are wonderful materials to consider in construction projects in UAE as they are powerful materials that perform well. The perforated sheets made of anodized aluminum and GI are very special and preferred in various projects. A modern sleek appearance is best achieved with anodized aluminum, and a functional and flexible solution with GI perforated sheets. Go to Visit Dinco.ae to understand more about these quality materials and receive the most suitable solutions to your problems.

FAQs

What is the main advantage of using Anodized Aluminium Sheets in construction?

The primary benefit of anodized aluminium sheets is their enhanced durability and corrosion resistance, which makes them ideal for both indoor and outdoor applications in harsh climates like the UAE.

Can GI Perforated Sheets be customized in terms of design?

Yes, GI perforated sheets are highly customizable. You can choose from different hole sizes, shapes, and patterns, making them perfect for various design applications.

How does anodization protect aluminium sheets?

Anodization creates a protective oxide layer on the surface of the aluminium, increasing its resistance to corrosion, abrasion, and weathering while enhancing its appearance.

Are GI Perforated Sheets suitable for use in coastal areas?

Yes, GI perforated sheets are ideal for coastal areas due to their galvanized coating, which provides a layer of protection against saltwater corrosion.

What are the most common uses of Anodized Aluminium Sheets in the UAE?

Anodized aluminium sheets are commonly used for exterior cladding, window frames, doors, and interior design elements due to their durability and aesthetic appeal.